Focus on automated cutting and automated welding

Service Hotline

Sales:158-6112-7223(Mr.Xie)

Technology:139-1232-1964(Mr.Liu)

Service Hotline

Sales:158-6112-7223(Mr.Xie)

Technology:139-1232-1964(Mr.Liu)

support hotline:

158-6112-7223

Product introduction:

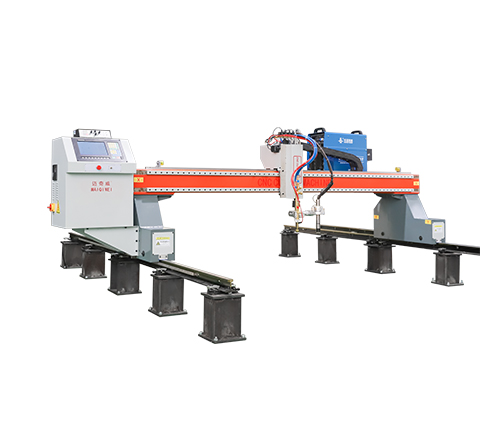

Machway light gantry CNC cutting machine, the bed is designed for wide body and low center of gravity gantry structure, steel structure parts all eliminate the internal stress processing, long-term guarantee factory precision; Equipped with stepper motor, drive and reducer; Drive gear and rack to achieve no clearance elastic meshing transmission; Implement bilateral symmetric drive mode; Longitudinal rail is made of 15kg high strength rail precision grinding; The machine runs smoothly, and the cutting torch positioning and reset is accurate. At the same time, it is equipped with flame and plasma cutting torch to adapt to the automatic cutting of different materials and plates of different thickness. The water storage tank can be configured under the cutting platform to reduce smoke and dust pollution during cutting. This machine implements the design of light weight, high speed and precision, small inertia, stable operation, easy operation and quick installation. In line with the national JB/T5102-99 standard; Cutting precision and quality to meet the national JB/T10045.3-1999 standard of A and I grade; Selected domestic front-line mainstream numerical control system (host), complete functions, simple and convenient operation.

Product advantages:

▲ According to customer needs can be selected with Beijing Starfeng, Shanghai Jiao Tong University and other brands

The host system:

▲ The track length and track spacing can be customized according to customer requirements

▲ The number of cutting torches can be increased according to customer requirements

▲ warranty period free on-site maintenance service, lifetime to provide maintenance parts

▲ Ensure that the whole machine has a high cost performance

Technical parameters:

| Name | Lightweight gantry CNC plasma flame cutting machine | ||

| specifications | MQW-3000QX | MQW-3500QX | MQW-4000QX |

| The input voltage | Single phase AC 220V± 10% 50-60Hz 1.0kW, plasma three-phase AC 380V | ||

| The input power | Stepping (1200W)/ Servo (2000W) | ||

| Cutting type | Plasma cutting (with plasma power supply)/flame cutting/plasma cutting + flame cutting | ||

| CNC span mm | 3000 | 3500 | 4000 |

| The length of the numerical control mm | 5000 (Length can be lengthened according to user's requirements) | ||

| Effective cutting range mm | 2400*4000 | 3900*4000 | 3400*4000 |

| Lifting height of cutting torch mm | 200 | ||

| Cutting torch and quantity | 1 set of plasma or 1 set of flame | ||

| Number of moving bodies | Standard 1 set, optional (at most 2 sets) | ||

| Plate cutting thickness | Depending on the plasma power, the flame is 6-150 mm | ||

| The running speed | 0—10000mm/min | ||

| Cutting speed | 20—6000mm/min | ||

| Driving type | Double side drive (rack and pinion drive) | ||

| The motor type | Standard 86 series stepper motor + reducer (optional servo motor) | ||

| Numerical control system | Beijing star peak, screen 10 inches large screen | ||

| Other configuration | Lifting pipeline drag chain, 1 set of tools | ||

| Gas supply requirements | The pressure of acetylene or propane is not more than 0.1MPa (flame cutting method is required) | ||

| Requirements for oxygen supply | The oxygen pressure is not more than 0.8Mpa (flame cutting mode is required) | ||

| Raise the type | Flame capacitance adjustment: optional/plasma arc voltage adjustment: optional | ||

| A mobile body can only support one type of elevation (for example, if plasma arc voltage elevation is optional, flame capacitance elevation cannot be added) | |||

| Nesting software | Standard: StarCAM small expert version/FastCAM set | ||

| Machine Tool Bare Package Dimensions | 3730*1000*1000 | 4230*1000*1000 | 4730*1000*1000 |

| Guide rail foundation, cutting rack | The manufacturer provides the drawing, the user makes by himself | ||