Focus on automated cutting and automated welding

Service Hotline

Sales:158-6112-7223(Mr.Xie)

Technology:139-1232-1964(Mr.Liu)

Service Hotline

Sales:158-6112-7223(Mr.Xie)

Technology:139-1232-1964(Mr.Liu)

support hotline:

158-6112-7223

Product introduction:

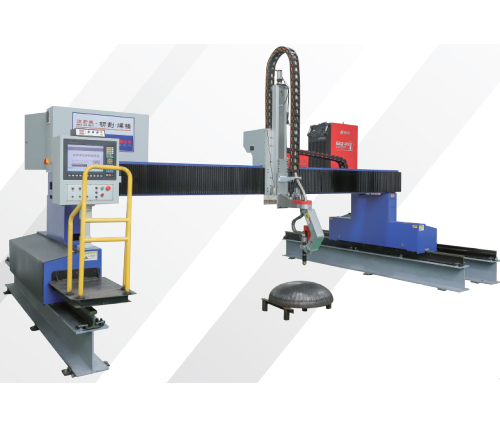

MQW - FT series gantry CNC sealing top ion cutting machine is my company in absorbing domestic and foreign advanced software and hardware technology, apply to the six countries table head, orange disc type spherical tank form a complete set of processing and self developed an efficient automatic cutting equipment, can be in the six countries table head anywhere, at any Angle cutting any graphics (round hole, square hole elliptic hole, etc.), At the same time, it has the function of plate cutting. Cutting surface roughness and high precision, small deformation. The machine has the advantages of reasonable structure, simple operation and advanced technology. The machine runs smoothly, cutting torch positioning and reset accurately, in line with the national JB/T5102-99 standard; Cutting precision and quality to meet the national JB/T10045.3-1999 standard provisions of grade A and Ⅰ.

The series of cutting machine components by numerical control system, drive system, control system, mechanical system, gas system. This machine is mainly used for six kinds of national surface head, orange disc spherical storage and irrigation supporting processing plasma cutting, complete functions, high degree of automation, advanced configuration, high precision cutting, good quality, good dynamic stability. CNC system, servo system using international well-known brands, excellent performance of products, high degree of humanization, convenient operation, rich software and high quality hardware configuration, a full range of protection measures to provide users with a high quality products.

Product advantages:

Dedicated head cutting for fitting Angle slope oral

Standard remote control, convenient for user operation

According to customer requirements can be selected with different power imported haibao, Victor (Feimat) or domestic brands of plasma cutting power supply

The number of cutting torches can be increased according to customer requirements

According to customer needs can increase the case of dusting line and so on a variety of other functions configuration warranty period free on-site maintenance service, lifetime to provide maintenance parts

Ensure that the machine has high performance and price

Technical parameters

| Name | MQW-FT gantry CNC sealing first-class ion cutting machine |

| Structure | Gantle type bilateral drive, Cartesian coordinate system (XYZ) +A rotation axis +B rotation axis +ZI elevation axis |

| Mainframe input power | AC 220V±10% 50-60Hz 4.0KW |

| Cutting way | Plasma cutting (with plasma power supply)/flame cutting is optional |

| CNC span mm | 3000-6000mm(Can be customized) |

| The length of the numerical control mm | 4000-16000mm(Can be customized) |

| Cut head diameter | 300-4500mm(Can be customized) |

| Head height | ≤1500mm |

| Effective cutting height of plate | 2000-5000mm(Can be customized) |

| Effective cutting length of sheet | 2000-14000mm(Can be customized) |

| Number of CNC moving bodies | Standard 1 (can be increased or decreased according to user requirements) |

| The thickness of the cutting mm | Depending on the plasma power, the flame is 6-250 mm |

| Travel speed | 0—12000mm/min(Can be set) |

| Cutting speed | 20—6000mm/min(Can be set) |

| drive | Double side drive (rack and pinion drive) |

| The motor type | Panasonic servo A6 series motor + reducer |

| Numerical control system | Beijing star feng display 15 inches large screen |

| Other configuration | Lifting pipeline drag chain, 1 set of tools |

| Gas supply requirements | The pressure of acetylene or propane is not more than 0.1MPa (flame cutting method is required) |

| Requirements for oxygen supply | The oxygen pressure is not more than 0.8Mpa (flame cutting mode is required) |

| Raise the type | Flame capacitance adjustment: optional/plasma arc voltage adjustment: optional A mobile body can only support one type of elevation (for example, if plasma arc voltage elevation is optional, flame capacitance elevation cannot be added) |

| Programmatically | Head cutting: system library parametric programming plate cutting: STARCAM programming software/FASTCAM programming software |

| Length positioning accuracy | 0.3mm/2000mm |

| Angle positioning accuracy | 0.1-0.2°/360° |